Sustainably sourced, AAR-certified friction mats engineered for reliable cargo securement. Cordstrap's AAR-approved rubber friction mats are designed to prevent dangerous cargo shifts across rail, truck, and intermodal shipments.

With industry-leading compliance and sustainable manufacturing, they are the safe, efficient, and environmentally responsible alternative to wood blocking and bracing.

Explore sizes and rolls on each subcategory page.

Low-profile industrial anti-slip mats are the go-to choice for palletized cargo, finished goods, and simple securement solutions. Adding high-friction grip without increasing load height or weight.

Extra grip for heavy-duty freight like bricks, steel products, and construction materials.

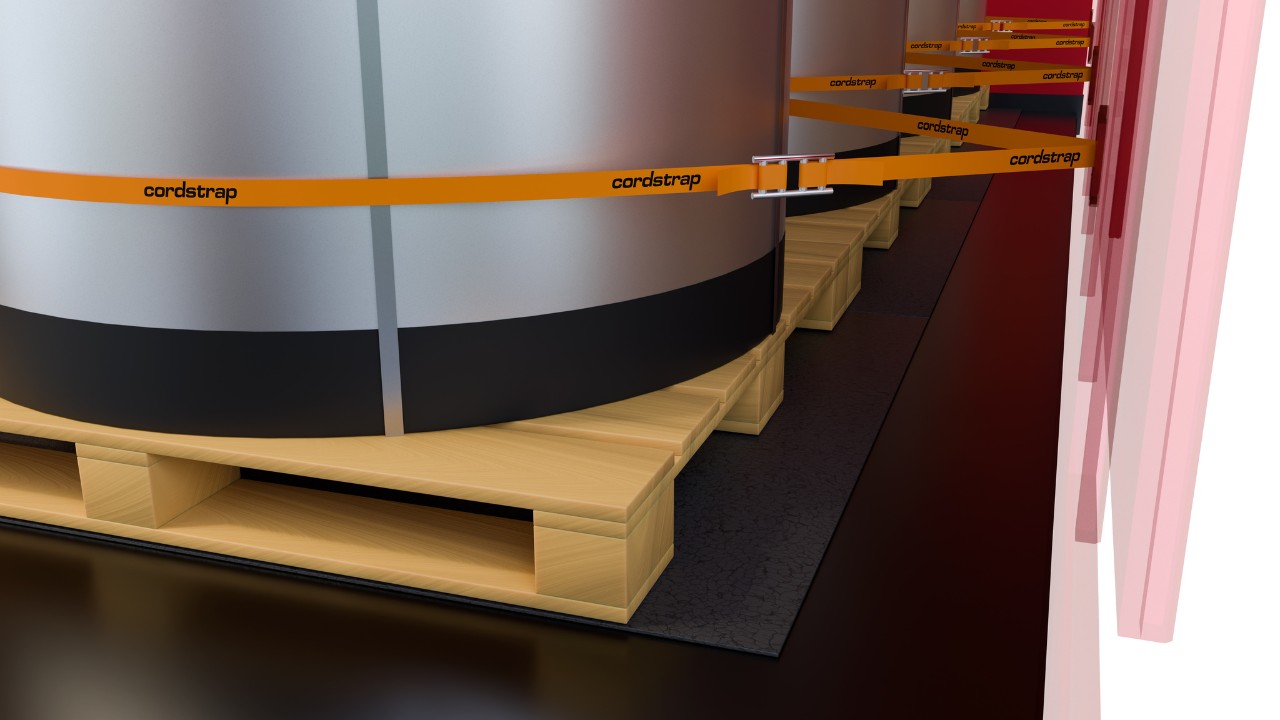

Extra-thick stability and shock absorption for metal coils and extreme loads.

Continuous rolls for flexible layout: 2 mm and 3 mm for general use; 6 mm for coils and extreme loads.

Watch this short demonstration to see how friction influences load stability. The video uses a tilting flatbed to show how a cargo unit reacts with and without a friction mat underneath, illustrating how added friction helps keep loads in place.

While the setup is simplified, the principle applies across transport modes: increasing friction between the load and the floor reduces the amount of blocking, bracing, or restraint needed to keep cargo secure. Cordstrap AAR Rubber Friction Mats deliver a verified COF > 0.8 in wet and dry conditions to support more stable, compliant load plans.

With a Coefficient of Friction (COF) > 0.8, Cordstrap mats exceed AAR performance criteria across transport modes.

For expert advice on cargo securing solutions contact us now

Contact now