Since 2014, Cordstrap has been working alongside U.S. steel producers to address one of the industry’s most complex challenges — safely securing structural steel loads on railcars.

These loads, known as “floating loads,” are designed to allow limited lengthwise movement during transit. When properly unitized and secured, they move very little and do not pose a threat of leaving the railcar. However, as the steel industry evolved, new shipment patterns created challenges that demanded an updated approach to load securement.

Over the past two decades, the steel industry has changed dramatically.

In the 1990s, distributors purchased steel in bulk quantities, holding large inventories of common beam sizes. This created uniform, consistent shipments, often entire cars loaded with beams of the same length.

Today’s “just-in-time” supply chain, however, has shifted that model. Distributors now order steel per project, resulting in mixed-length loads and new securement challenges for manufacturers.

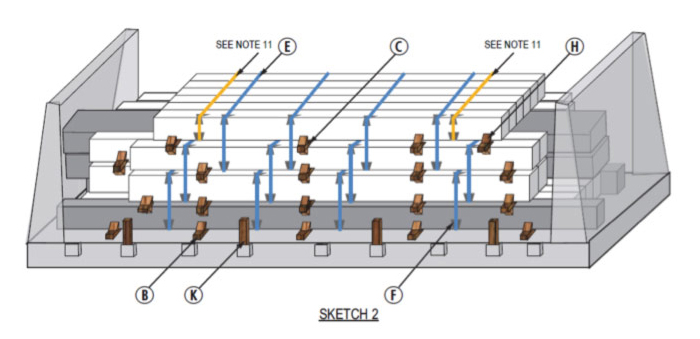

A single railcar might now contain beams ranging from 40 to 60 feet in length, stacked pyramid-style with significant voids between the ends of the beams and the bulkheads. When these cars experience impacts during switching or humping, shorter top layers can shift, causing uneven force distribution and placing extreme stress on traditional steel banding; often causing it to break.

In 2014, this challenge culminated in a major two-train accident.

One train carrying structural steel was moving through a super-elevated curve when several beams slipped off the car, just as another train passed in the opposite direction. Fortunately, no one was injured, but the incident caused an estimated $21 million cleanup and brought industry-wide attention to the need for safer, more resilient load securement.

Within one week of the incident, Cordstrap’s Rail Team was on-site with a major U.S. steel manufacturer. Working closely with engineers and regulators, Cordstrap developed and tested new non-metallic securement methods. Within days, Cordstrap became the first company to pass a formal AAR impact test using non-metallic banding for structural steel.

Over the next four years, Cordstrap continued collaborating with the AAR and major steel manufacturers to develop improved loading solutions. A key breakthrough came from investing in new steel edge protection technology, allowing non-metallic straps to withstand the sharp edges and high tension typical of structural steel applications.

This innovation paved the way for a successful field trial — and in June 2017, the AAR published Structural Steel Figure 109, formally approving the use of non-metallic strapping for securing steel beams on railcars.

This milestone gave manufacturers a safer, stronger, and more efficient alternative to steel banding, changing how structural steel is shipped across North America.

Cordstrap’s work didn’t stop there. In September 2017, the company conducted another formal AAR impact test for a new load plan designed to increase beam-loading capacity per railcar.

The test was a success, and additional field trials were scheduled soon after — marking yet another step forward in improving both safety and efficiency for steel shippers.

Cordstrap continues to lead the industry in developing AAR-approved securement solutions for structural steel and other complex loads.

Our North American Rail Team, now 15 field experts strong, partners directly with manufacturers to diagnose problems, create custom load plans, and deliver safe, compliant, and innovative solutions for every type of rail shipment.

For more information or to discuss your specific rail-loading challenges, contact our team today.

For expert advice on cargo securing solutions contact us now

Contact now