Since its launch in 2012, Cordstrap’s patented Dynablock® portfolio of buckles has become the first choice for railroad shippers across North America. Known for their strength, reliability, and safety, Dynablock buckles have set the standard for AAR-compliant cargo securement.

Now, Cordstrap is proud to announce a new generation of improvements designed to make these industry-leading buckles even safer, easier to inspect, and more reliable in demanding rail environments.

Training and Application: Getting the Most from Dynablock

Every purchase of Dynablock buckles includes on-site support and training from a Cordstrap Field Representative. During this session, our expert ensures that straps are applied correctly to take full advantage of Dynablock’s advanced locking technology.

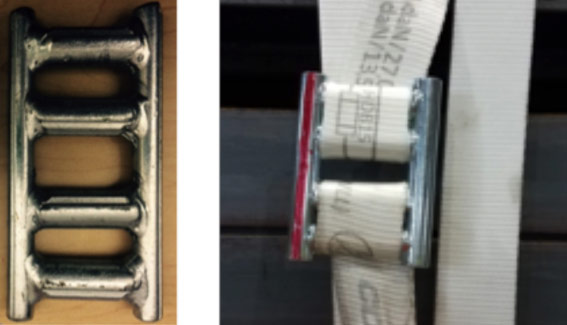

Each buckle features distinctive grooves running the length of one side, allowing operators to see and feel the correct orientation instantly. This simple design feature enables visual confirmation of correct application from up to 8 feet away — a major benefit for busy loading sites and safety inspections.

Innovative Groove and Knurling Technology

The opposing angled groove design of the Dynablock buckle allows the strap to be tensioned from either direction without resistance. Once tensioned, the knurled posts act like micro barbs, gripping the strap securely and preventing any backward slip.

For dynamic loads, especially those exposed to rail shunting and hunting forces, Dynablock buckles are a shipper’s best defense against slippage. When applied correctly, zero strap movement occurs, eliminating the need for re-tensioning during transit and maintaining cargo stability under even the harshest conditions.

Introducing the High-Visibility 3rd Generation Dynablock

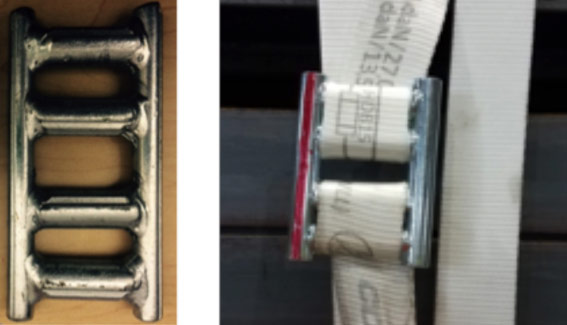

Building on years of field feedback, Cordstrap has now introduced the 3rd Generation Dynablock, featuring a high-visibility reflective red marker.

This permanent reflective stripe allows operators and inspectors to instantly confirm correct buckle orientation from over 15 feet away, streamlining compliance checks and improving loading-dock safety.

When you see the red stripe — you know your cargo is secured with the most advanced strapping and buckle technology available worldwide.

2nd Generation” Dynablock 3rd Generation” Dynablock with hi-viz marker

The Cordstrap Commitment to Safer Shipping

At Cordstrap, safety isn’t just a feature — it’s our mission. Our 15-member North American Rail Field Team works closely with customers to deliver training, demonstrations, and on-site technical support, ensuring every product performs flawlessly in the field.

If you’re still using traditional steel banding or non-optimized buckles, now is the time to upgrade.

Contact our team today to schedule a demonstration or quote — and experience how Dynablock can make your rail shipments safer, faster, and more compliant.

Get in touch here.