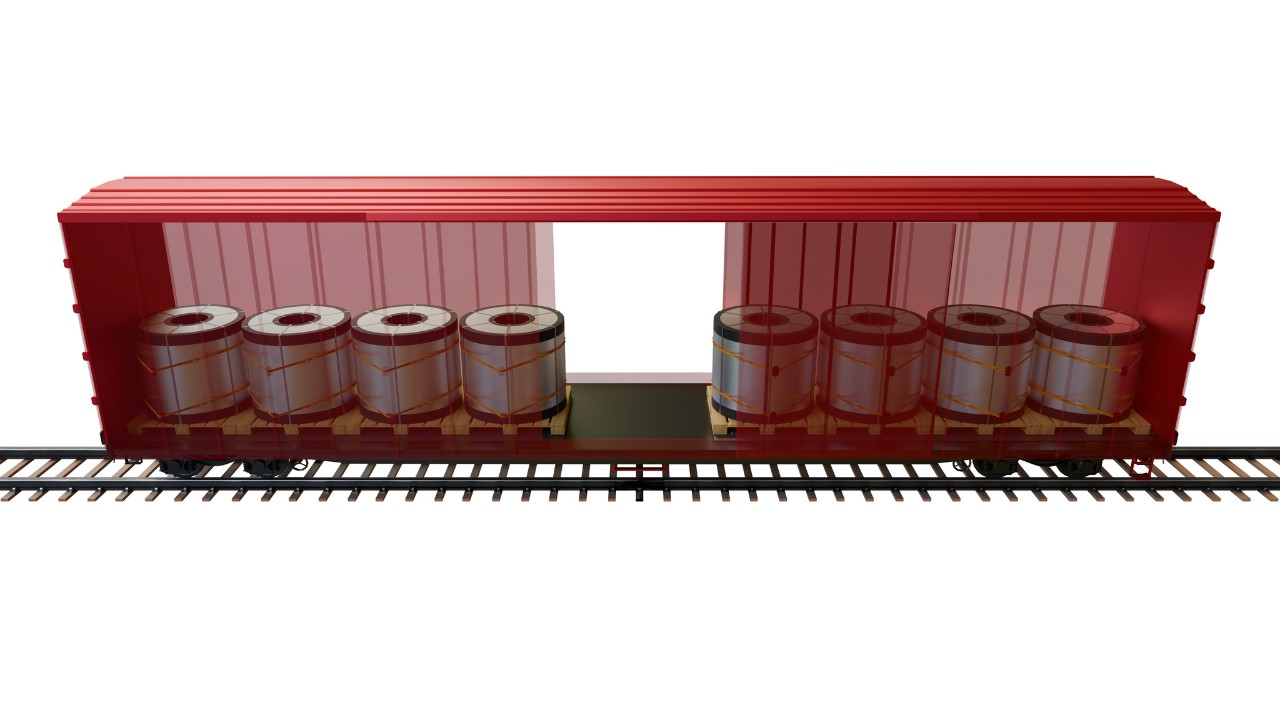

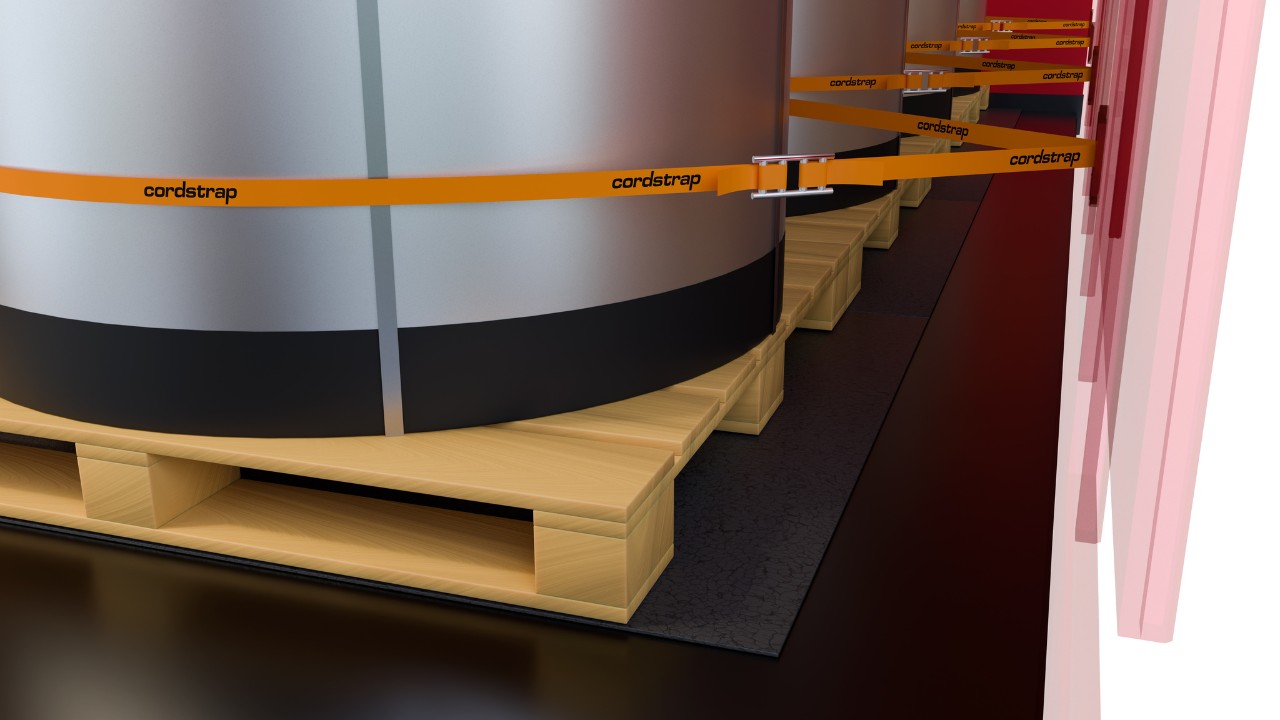

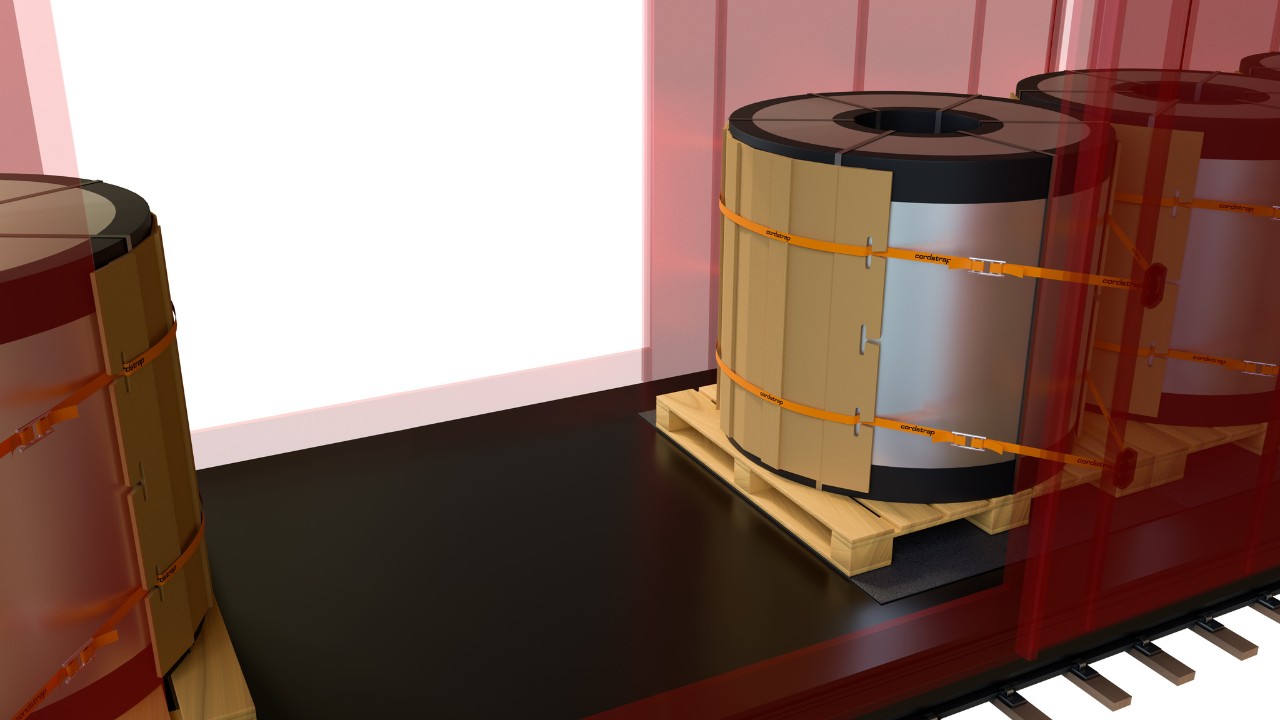

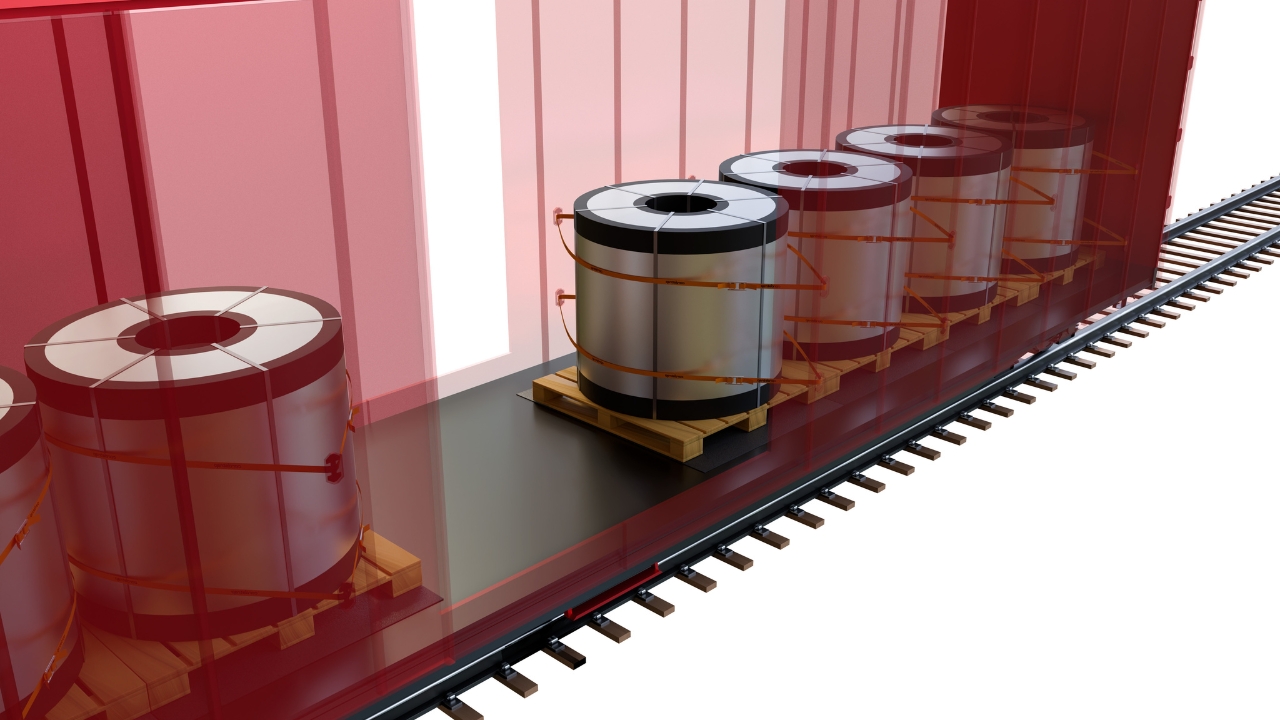

Non-Metallic Strapping

Cordlash 200 & Cordlash 750

AAR-verified systems for safer, lighter closed car coil securement.

- Delivers web-assembly integrity at lower weight

- One-way design removes hardware-reuse risk

- Higher, consistent tension via battery tensioners